Concrete Anode – CP-X

Zinc anodes are widely adopted for cathodic protection of steel in concrete in corrosive environment. The chemical composition and electrochemical properties of the anode are covered by the ASTM-B418 Type-I. The anode is covered by a specially formulated high alkaline porous cementitious mortar.

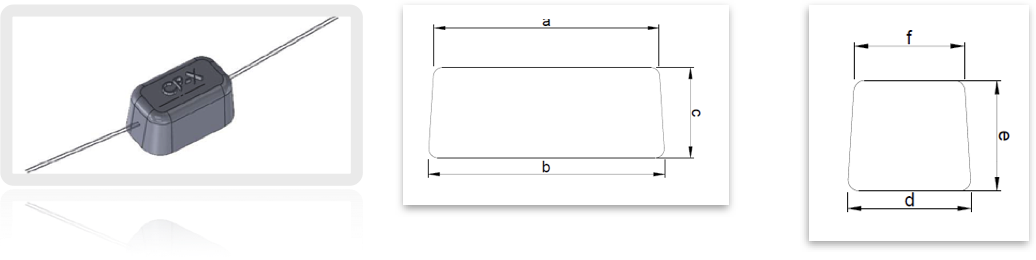

KORTEK galvanic concrete anode series CP-X with fully in-house designed, developed, manufactured and first introduced with 160 gr/nett model. Dimensions are as below;

| CP-X Anode Dimensions | |||||

|---|---|---|---|---|---|

| a, mm | b, mm | c, mm | d, mm | e, mm | f, mm |

| 100 | 105 | 40 | 50 | 40 | 40 |

| Zinc Anode Weight | 160 gr | ||||

| Galvanised connection wires total length is 50 cm. (18 ~ 20 cm each side of anodes) |

|||||

Application

Application

- The anode is tied to the surrounding reinforcement bars through its galvanized wires.

- The anodes are uniformly distributed based on the steel surface area.

- The anode performance and service life depends on many factors which are concrete conductivity, steel density, spacing of the anodes, concrete cover thickness, humidity, whether the anodes are used for corrosion prevention (existing structure repair) or corrosion control (new structure), pH of the concrete, temperature etc.